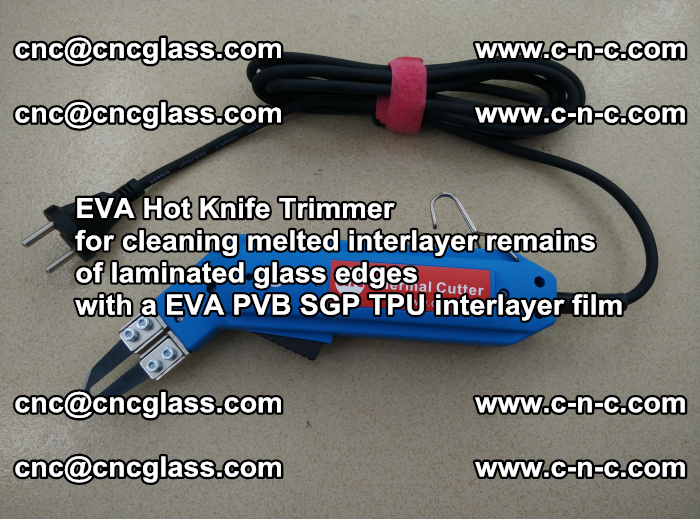

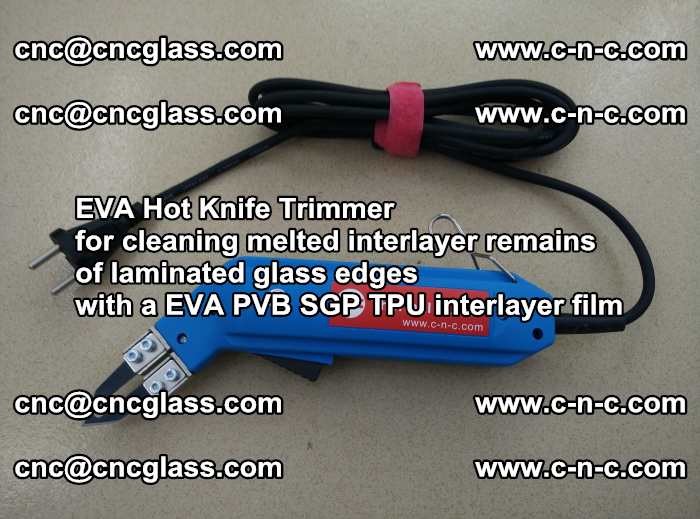

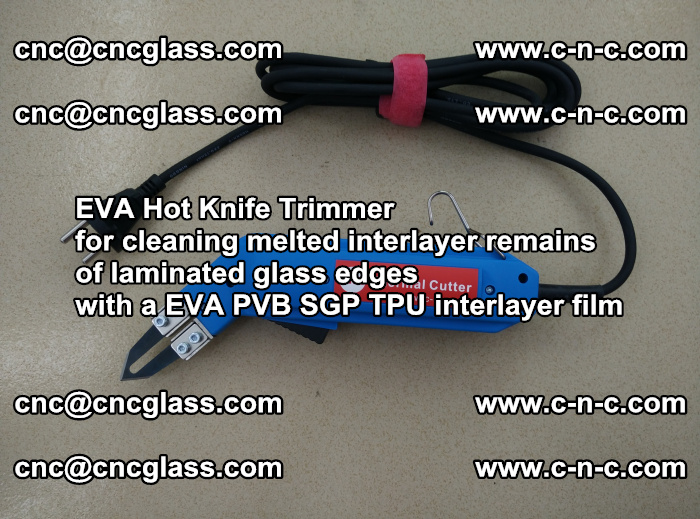

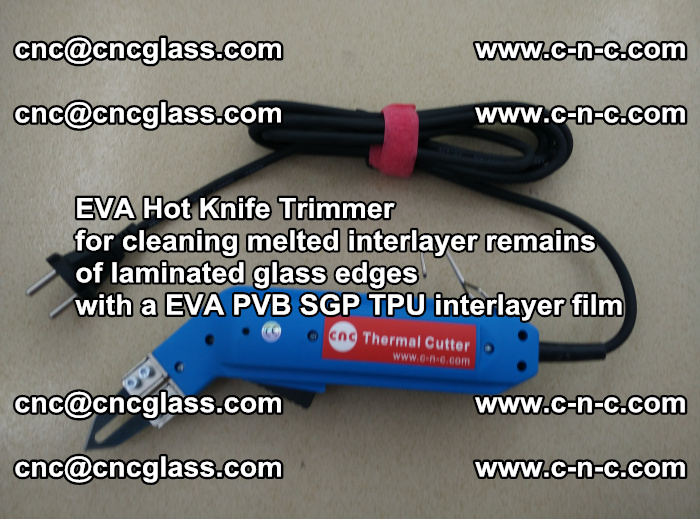

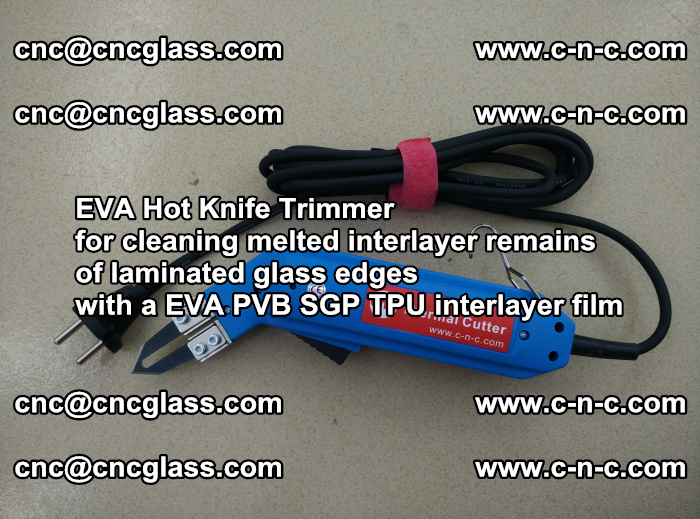

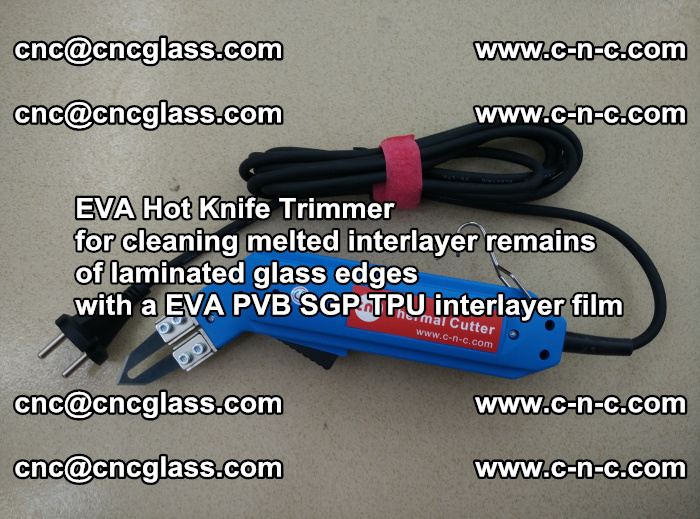

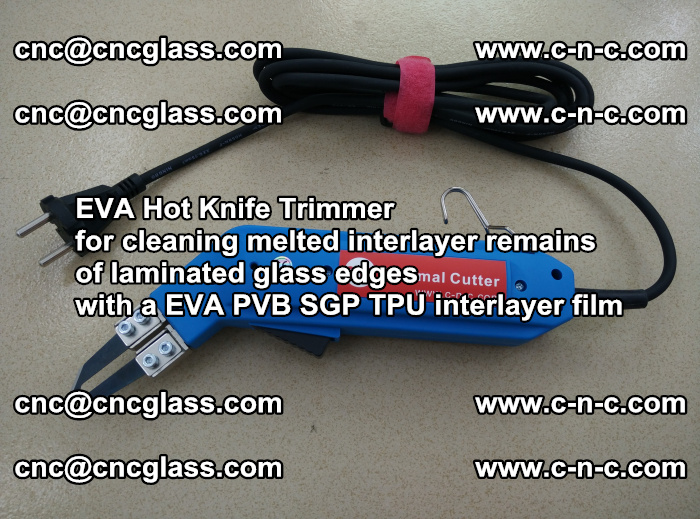

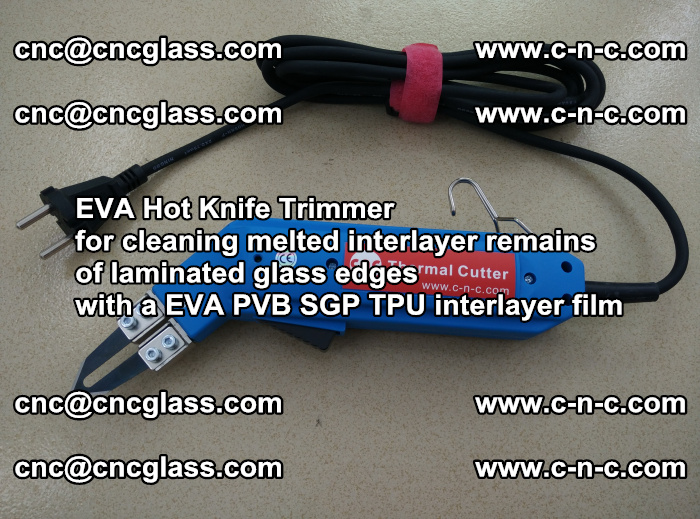

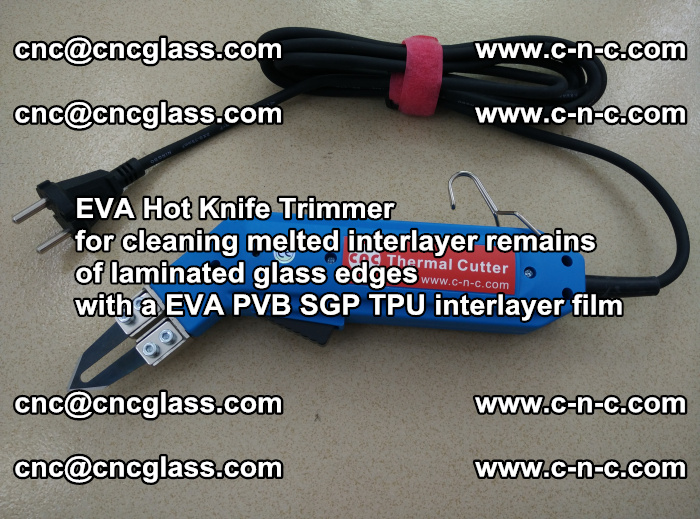

Thermal Cutter Trimmer for cleaning interlayer remains of laminated glass edges with a EVA PVB SGP TPU interlayer film

Cautions of EVA film safety gazing vacuuming machine

1.1.2

The prevention of injury, should take the following:

For equipment operators should be subject to induction training, with equipment operation skills, be able to correctly understand this statement and other random information.

The operator to enter the workplace should wear insulated shoes, do not wear loose clothing style.

And the operator to wear protective gloves to prevent hand touching glass and glass-plastic folder which has not been fully released after cooling.

When heating and vacuum process work, don’t put hand on the door of vacuum pump, to avoid high-temperature hot.

The interlayer film materials to be processed should not release toxic, and irritating smell of gas. Otherwise, there should be adequate protection measures to prevent inhalation of these harmful gases, such as to exhaust harmful gases into the appropriate place.

When open the door of the furnace, in order to avoid excessive inhalation of the odor release, you should appropriate wear masks.

Take-off and landing with forklift loading and unloading of glass should be careful not to hand on the rope and the rope round.

When cooling fan working, don’t put hands on the cooling fan.

High maintenance to pay attention to safety, take prevention measures to prevent the fall. Care staff if necessary.

The operation of the collision is to be careful to pay attention to avoid the hook. hook loading construction should remove to the highest position

In order to avoid loading and unloading by forklift fork arm tripping over, don’t use loading and unloading forklift truck, the fork arm should be moved to the lowest position. At the same time, should also be noted the lower car to prevent tripping.

Equipment containing asbestos insulation materials, insulation materials in the replacement or removal of equipment at end-of-life, measures should be taken to wear appropriate masks, protective clothing and gloves and work shoes, to avoid direct contact and inhalation of asbestos dust.

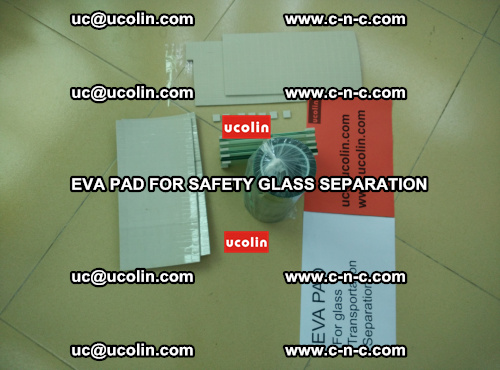

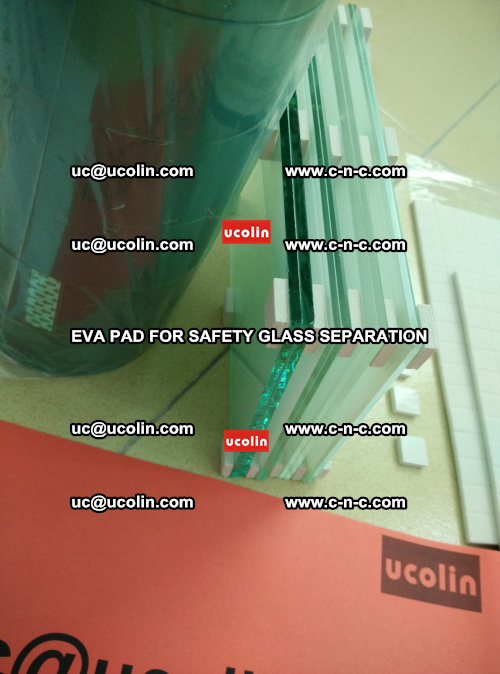

EVA PAD glass cork pad for safety laminated glass delivery

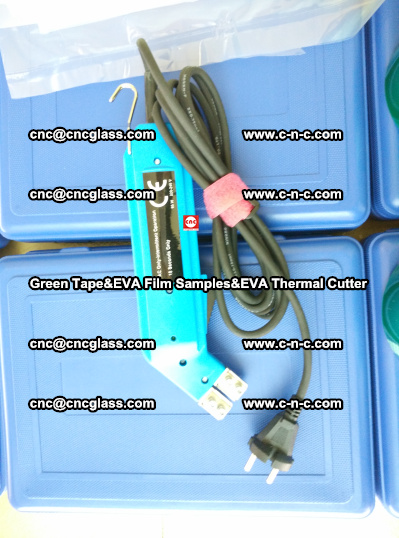

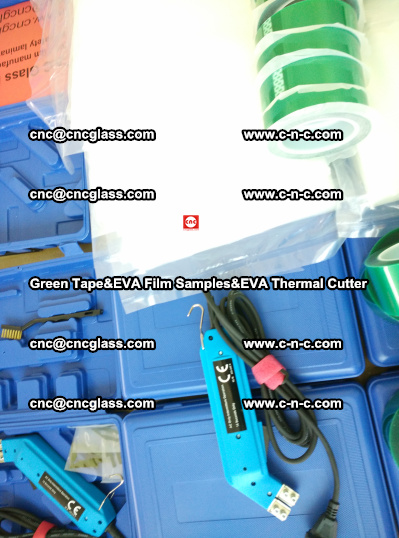

Green Tape, EVA Thermal Cutter, EVAFORCE SPUPER PLUS EVA FILM

Comparing Tensile Strength of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

Written by Peter Lin

Tensile Strength Test of Super Clear EVA Film Samples of an international famous supplier

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: Super Clear EVA Film Samples of an international famous supplier

4-Speed: 300mm/min

5-Laminating Time and Temperature: 85°-15′130°-40′

No. Max

(N) Tensile Strength

(MPa) Elongation

(%) Young’s modulus

(MPa)

1 78.934 18.794 633.768 1.337

2 62.488 15.622 664.459 1.060

3 69.637 16.580 639.186 1.207

4 55.525 13.543 584.743 0.991

5 64.980 15.471 610.706 1.124

6 65.921 16.078 610.949 1.177

7 62.449 14.193 607.018 1.001

8 61.194 14.570 622.803 1.014

9 55.506 13.538 592.248 0.983

Max. 78.934 18.794 664.459 1.337

Min. 55.506 13.538 584.743 0.983

Average 64.070 15.377 618.431 1.099

Tensile Strength Test of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: EVAFORCE EXTREME of CNC Glass Interlayer

4-Speed: 300mm/min

5-Laminating Time and Temperature: 85°-15′130°-40′

No. Max

(N) Tensile Strength

(MPa) Elongation

(%) Young’s modulus

(MPa)

1 78.895 19.243 528.706 1.553

2 66.264 16.162 519.201 1.337

3 85.044 21.261 554.858 1.630

4 71.030 17.324 534.723 1.371

5 68.706 16.757 533.400 1.324

6 66.205 16.148 482.024 1.464

7 76.561 18.673 543.838 1.457

8 68.382 16.281 484.427 1.471

9 89.015 21.711 565.189 1.642

Max. 89.015 21.711 565.189 1.642

Min. 66.205 16.148 482.024 1.324

Average 74.456 18.173 527.374 1.472

Conclusion:

EVAFORCE EXTREME of CNC Glass Interlayer performs better tensile strength and Young’s modulus than the international famous supplier’s Super Clear EVA Film samples.

EVAFORCE EXTREME super clear EVA interlayer film is the first world-class level .interlayer for safety laminated glass.

EVA FILM

EVAFORCE® EXTREME

*Super Clear

*For Architectural Safety Laminated Glass

*Less Overflow When Heating

*Strengthened Mechanical Properties

*Recommended For Extreme Environments

*Best Choice For Curved Glass Laminating

*Applied Both Indoor And Outdoor

*Replacing PVB Film

Silicone Vacuum Bag for EVALAM TEMPERED BEND lamination

Silicone Vacuum Bag for EVA Glass Laminating Machine&Autoclave

By Zac Lynn

+The combination of the silicone bag:

-Upper Silicone Sheet

-Down Silicone Sheet

-Edge Gear

-Silicone Tube

+Technical Parameters of Silicone Vacuum Bag

Tensile strength

Tearing strength

Hardness

Breaking extensibility

Color

Pattern Temperature Resistance

6.5(Mpa) 26(N/mm) 55±5(Shore A) 450% Transparent

One smooth

One cloth grain 230 °C

+Description:

-Product Purpose: used for glass vacuum laminating machines to make

safety laminated glass with EVA FILM INTERLAYER, or for making privacy glass, switchable glass with PDLC FILM and EVA FILM

-Product features: heat-resistant, aging-resistance , anti-corrosive,environment-friendly, Long-use life, good resistance

+Product specification:

1) common thickness: 3mm

2) maximum width:3800mm with no joint

3) any length

4) common color: transparent,red, and any color available

5)Customization is available as customers require

+Notes When Using the Silicone Vacuum Bag

-Please edging the glass before laminating, which can prohibit the sharp glass edges of the glass cut the silicone bag.

-Use tape to seal the pre-laminated glass to reduce the EVA leaking from the laminated glass.

-Use some papers/fabric to cover the silicone bag to separate the EVA from the silicone bag

-Put some wires net on the vacuum hole to help vacuuming.

-When not laminating , put the silicone bag out of the hot oven.

+ Procedure of Ordering:

(1)Be ware of the kind of silicone you need: for EVA glass lamination or for solar encapsulation.

(2)If you need silicone vacuum bag for EVA glass lamination, please offer the internal size and external size of the silicone bag.

(3)If you need silicone rubber sheet for solar encapsulation, please offer the thickness, width, length.

All rights reserved by

UCOLIN SILICONE

SILICONE VACUUM BAG FOR EVA LAMINATING MACHINE

SILICONE VACUUM BAG FOR PVB AUTOCLAVE VACUUMING

ucolin@ucolin.com

www.ucolin.com www.silicone4.com